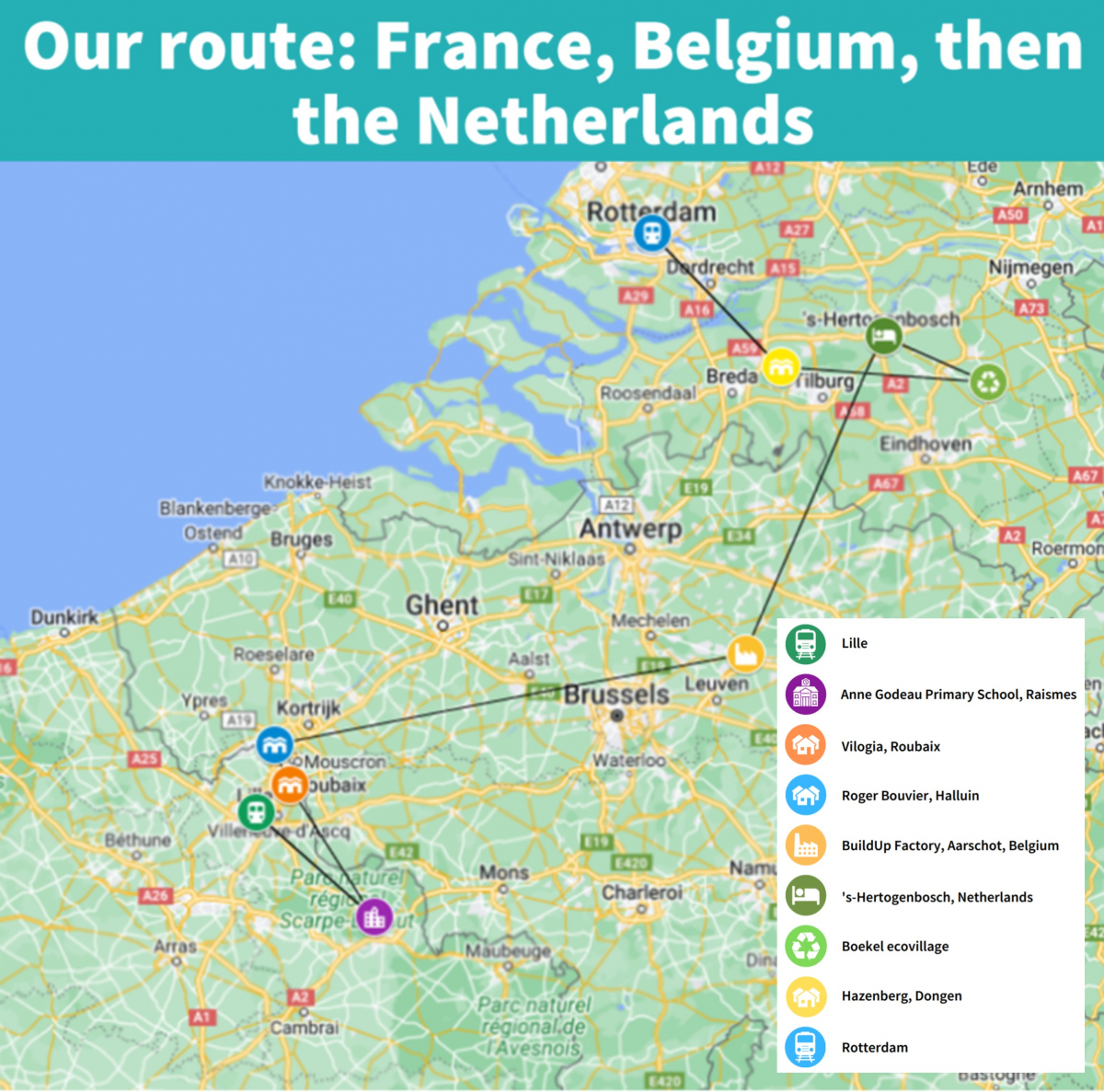

The Net Zero Heat European Study Tour was an insightful and inspiring journey, providing valuable insights into the solutions for decarbonizing heating in buildings. Organized by Energiesprong UK and Innovate UK, the tour aimed to foster collaboration and inspire the sector to develop cost-effective routes for retrofitting buildings with net zero heat solutions. In this blog post, I will share my reflections and key learnings from the study tour, which took us to France, Belgium, and the Netherlands.

Le tour

The tour spanned three days and included visits to various building sites, workshops, a factory tour, and an ecovillage.

French facades

Our first stop was France, where we witnessed the challenging retrofit of the country's first Energiesprong school. The project focused on strengthening the existing concrete structure and adding external wall insulation with a timber stud frame and prefabricated facade panels. However, there were concerns among the cohort about the air tightness measures and the “bio-based” insulation materials appeared to be mineral wool - something lost in translation perhaps?

We also had the opportunity to explore a social housing retrofit in France, featuring BuildUp's offsite EWI panels. Afterwards, we learned about the pioneering work done by Vilogia, France's third-largest private social housing provider, in upgrading their housing stock through innovative projects such as this.

The Belgian BuildUp

Moving on to Belgium, we had the chance to visit BuildUp’s manufacturing site. The relatively new company specialises in steel frame systems for off-site retrofit and new build. It was inspiring to witness their streamlined design process, leveraging AutoDesk digital tools. The CEO of BuildUp, Helene, openly discussed the challenges faced by the nascent retrofit market and the journey to achieve product-market fit.

Dutch demonstrators

In the Netherlands, we attended a workshop in Den Bosch, where Eveline Molier from the Department of Building and Energy shared insights into the Dutch Government's policies to support a mass retrofit revolution. Notably, the energy service charge and the archetype-focused approach were discussed as means to overcome barriers and promote widespread retrofitting. However, it was emphasized that there is still progress to be made in establishing one-stop-shops for homeowners and reducing costs.

One of the highlights of the tour was the visit to EcoDorp Boekel, an innovative community housing project in the Netherlands. The project showcased the use of bio-based insulation materials, thermal energy storage, DC power, MVHR, greywater systems, and reed bed wastewater treatment. The massive thermal energy storage unit, utilizing blast furnace slag surrounded by insulation, demonstrated the potential for sustainable district heating solutions.

Finally, in Dongen, we explored Dutch Energiesprong retrofits that couldn't utilize off-site SIP panels due to structural limitations. These properties underwent on-site treatment with traditional methods, including 300mm of EPS wall insulation, solar panels, and FactoryZero rooftop energy modules.

Reflections & learnings

Reflecting on the tour, it became evident that the high-performance building retrofit market is still in its infancy across Europe. The key challenge lies in overcoming the limitations of the currently insufficient skilled labor force. Retrofit projects, although promising, remain at the pilot scale and require grant funding, with costs exceeding EUR 100k per property. Achieving the economies of scale necessary for mass roll-out of whole-house retrofit solutions is still a considerable hurdle.

Off-site progress

The benefits of off-site solutions were apparent, particularly in terms of speed and performance. Social housing providers, in particular, can benefit from reduced labor, minimal disruption, and quicker portfolio upgrades. However, off-site manufacturers are facing acute challenges due to fluctuating demand. Companies like BuildUp and Beattie Passive are diversifying across new build and retrofit to mitigate these issues. Automation of design and planning processes is also being prioritized before investing in capital-intensive automated manufacturing facilities.

Bio-based insulation

Policy-wise, there is a growing focus on bio-based materials and embodied carbon in France and the Netherlands. However, it remains uncertain if this emphasis is translating into tangible changes on the retrofit sites visited. Dutch Government and Energiesprong are exploring the possibility of nationwide aggregation of archetypes to scale up retrofit solutions. They are also considering a staged approach to retrofit, prioritising straightforward fabric improvements before addressing M&E services, to keep costs down.

Shift to electrification is happening

Another significant aspect we observed was the impact of electricity prices on heating choices. In France, the cheap cost of electricity made heat pumps financially attractive. Considering the potential rebalancing of gas and electricity prices in the UK, there may be a shift in favor of heat pumps if (as is widely expected) green levies on electricity are removed. Further rebalancing could also potentially be funded through general taxation to subsidise electricity, ultimately leading to taxes on gas.

Are we seeing the sparks of the Retrofit market, finally?

To summarise, the study tour provided a comprehensive overview of the state of the market, off-site solutions, and policy considerations for decarbonizing heating in buildings. While challenges and barriers still exist, the tour showcased the tremendous potential and innovation in this field. Collaboration between industry, government, and other stakeholders will be vital in driving forward cost-effective and scalable solutions for achieving net zero heat in buildings.